We also introduced the applications for 3D printing when it comes to RHA and some of the things we use 3D printing for in developing our products (basically, why we’re writing this blog), so if you’ve not had a read over the first part, be sure to visit it before venturing on.

If you’re primed and set for another round of 3D printing knowledge, let’s go.

What are the advantages?

The proponents of 3D printing argue that the technology should be embraced, supported and a source of excitement for a number of reasons, both ideological and practical. One of the reasons that 3D printing is appealing to creative industries is the removal of the distance between product designer and manufacturer. In an ideal situation, a product designer could create and print an object himself, without the need to worry about third parties interfering or compromising the design. In the prototyping process, designers can take an idea from conception to reality in a tiny fraction of the time it would take to have factory-run models created.

The level of detail that can be produced by 3D printing objects has two advantages. Firstly, 3D printing can produce unique shapes and unrestricted profiles that are impossible to manufacture using other methods; they can also print items with semi-complex mechanisms that work straight out of the printer with no assembly required. The second advantage is the opportunity to individually customise and personalise 3D printed items. Unlike traditional production methods such as injection molding which require machine tools to create a large quantity of identical items, 3D print runs can be as small or as large as the user needs, and each item can be customised during that run for a unique version of the item.

One of the most practical uses of 3D printing is the possibility to print replacement parts for faulty or broken products. For example, the disk tray on a BluRay player breaks; rather than send it away for repair, or replacing it altogether, if the customer has a 3D printer, the manufacturer could email the 3D artwork of the part, and the consumer can print and replace the broken tray themselves. This system has the benefit for the consumer of avoiding delay in having a working product again, and for the manufacturer, is cheaper than replacing or repairing the product. There are concerns on how a system like this might affect product warranties, but the level of convenience for both the consumer and manufacturer is greatly increased.

Another argument for 3D printing is the potential to reduce wastage in production. Each year businesses lose millions in faulty products when defects are discovered either in the market, or within the production line. These products usually have to be recalled and refunded or replaced if already on sale, or scrapped if still being manufactured. This has both environmental and cost implications, but with 3D printing, this threat is removed. If each product is custom made to order there is very little chance of faulty products entering the market, and no chance of large quantities of products having to be made into landfill.

So with all these advantages, why aren’t we 3D printing everything, right now?What are the drawbacks?

Cost is a major drawback of 3D printing at consumer level. The material (plastic) used for printing the headphones mentioned in part one and purchasing the non-printed electrical components would cost more than purchasing a set of pre-made headphones, which would also have the benefit of having been developed specifically with audio quality, comfort and durability in mind. Similarly, because of their relative scarcity, 3D printing centres are able to charge premium prices for creating other people’s designs. It’s expected that both the cost and time that are involved in 3D printing will improve as the technology continues to advance, but at the moment, it is far from the cheapest method of production.

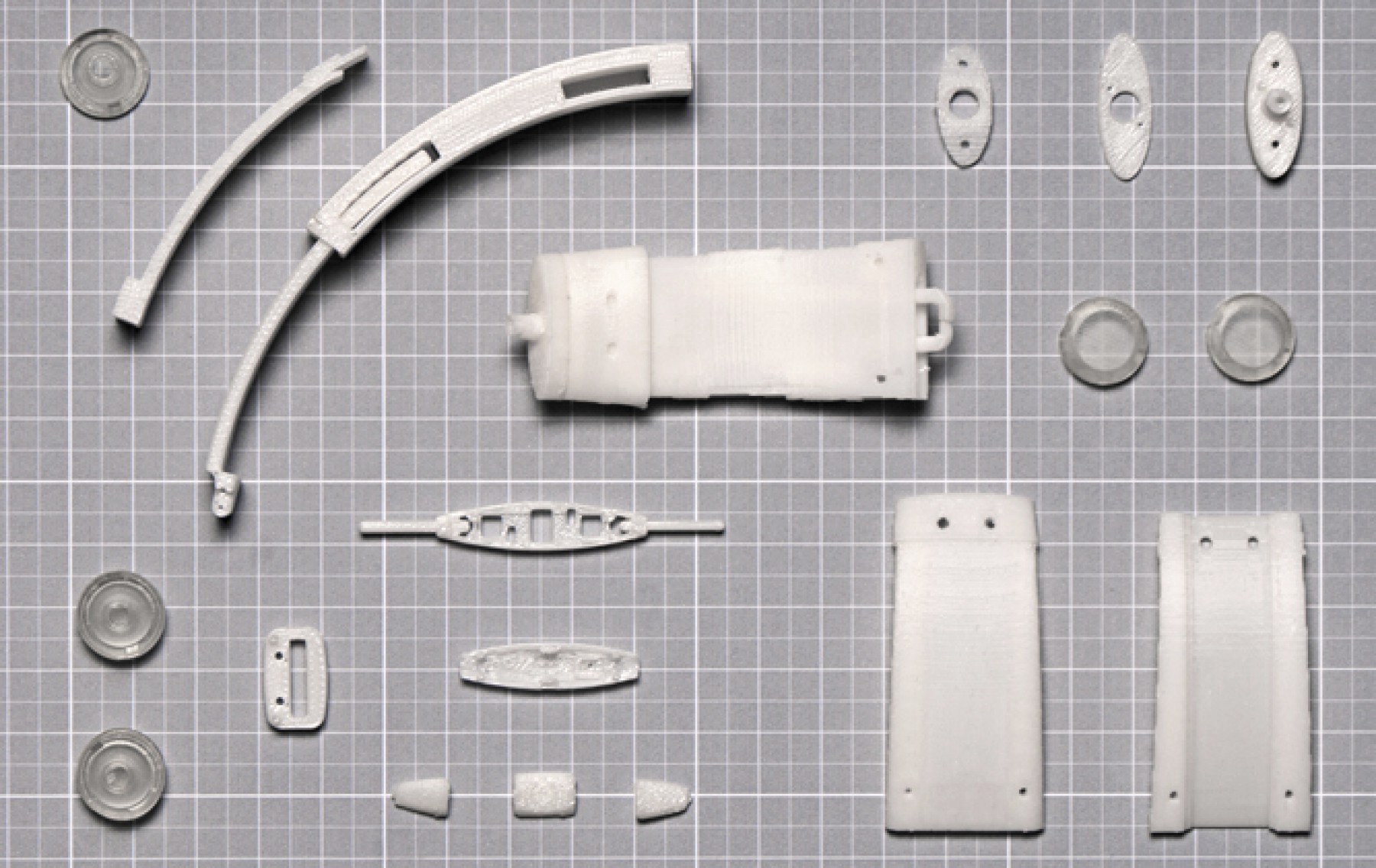

There’s also a question about the quality of 3D printing. While home 3D printers using FDM technology can be picked up for less than £500, the quality of product that these consumer machines are capable of producing can vary wildly. We noted in part one that RHA use stereolithographic printing for our product prototyping; the printers which produce these items to the standard we require cost tens of thousands of pounds. For creating items with a practical function, and needing reliable results, the current, low level, consumer version of the technology is not up to scratch. Take a look around reddit’s 3D printing subreddit, and see for yourself the kinds of items being printed by home 3D printers.

There are also a lot of legal questions to be answered before 3D printing reaches its apparent potential, with patent and copyright law worryingly light on casework and precedent for cases involving 3D printed designs. While there is a core user-group embracing the open source nature of home 3D printing supported by online communities such as RepRap and Thingiverse, there have also been cases of companies issuing cease and desist orders to halt allegedly copyright-infringing designs from being shared. Like all new technology, 3D printing will require a new set of legal standards which could help or hinder the technology’s progress.

One of the major disadvantages of 3D printing at the moment is that it is largely inaccessible to those outwith the enthusiastic early adopter community. While the technology is becoming more and more readily available, the form of the technology that is currently on the market is not designed for widespread consumer usage. There is yet to be a version of either the 3D modelling technology or the printer hardware itself that is simple and easy enough for the majority of people to use in their home. Until there is an all-in-one system with easy-to-use software, 3D printers are unlikely to become ubiquitous and are more likely remain the tools of product designers and hobbyists. Should this be the case, funding into advancing the technology is unlikely to be sustained and it may be that high quality home 3D printing units never make it to market.

The final potential hindrance to 3D printing is that it needs the support of businesses in the manufacturing industry. The idea of printing replacement parts for a faulty product is excellent, unless the manufacturer refuses to give you the design to print the part, or threatens legal action should you attempt download a similar design from the internet. Nokia have set an example for other companies by releasing a downloadable case design for its flagship Lumia 920 phone that customers can print at home, but will other companies be as quick to get onboard with 3D printing? It is easy to draw parallels between the growth in 3D printing and the advent of the digital music revolution, and by extension, between manufacturers and record labels. When Napster began the trend of digital music sharing via peer-to-peer networks in 1999, record labels quickly moved to shut down the service on legal grounds, rather than developing methods of legal digital music distribution. It wasn’t until the iTunes Store arrived in 2003 that users were actually offered a legal alternative method of procuring music files and record companies were able to monetise the practice of downloading music.

How does this relate to 3D printing? Supporters of the technology argue that the same negative reaction by manufacturers to 3D printing will only serve the same purpose as it did for the record labels - to cost them large amounts of money in legal proceedings, and be largely futile in stopping illegal practices. They argue that companies need to skip the phase of trying to stop the creation and sharing of potentially illegal 3D designs and move straight to establishing channels where consumers can legally download and print their own components, parts and even products. Without the support of companies and option to take steps to work with 3D printing legally, the 3D printing market may never get off the ground. Would consumers be tempted to invest in an expensive piece of equipment that’s if all that is available to them to use it for is printing illegal, unauthorised designs of uncertain quality and dubious legality?

So is 3D printing really the future?The progress made in 3D printing in the past few years has been incredible; from a fringe technology to ‘the next big thing’, the rate of acceleration in the quality of the product and its adoption make it hard to predict where it could be in a few years from now . Developments are being made every week to enhance, improve and streamline the machines, and early adopters are creating more and more experimental items and sharing their designs in online communities. There’s certainly potential in the technology, and some of the potential applications could have a huge impact on our lives, particularly those relating to the field of medicine..

If these statements seem fairly non committal, it’s because for all the excitement and potential of 3D printing, there’s absolutely no guarantee that the potential of the technology will be fully realised. Some statements are especially grandiose, and are purely part of the hype around the product, such as the idea that it’ll be commonplace for everyone to print and assemble whole products within their own homes. Consider that when 2D printers became commonplace, there was no rush for users to print the complete works of Dickens.

Right now, for every groundbreaking project idea such as 3D printed organs, there are hundreds of hobbyists making two inch sculptures in their bedrooms. It’s all about perspective, and while 3D printing might be the tech media’s darling for now, overcoming the potential drawbacks of the technology and advancing it to a sufficient standard to make it ubiquitous will not be an easy task. 3D printing may not be a new technology, but it is still a young one, and without a lot of care, effort and work, it might not turn out so great as it grows up.

So will 3D printing revolutionise the way we make almost everything? It’s a bold statement to make, but if people in positions of power, with the resources to fund development and research in the technology are convinced, maybe we should all be.

So that’s roughly everything you need to know about 3D printing, right now. There’s obviously a lot more going on and a lot more material to read up on if you’re really interested on where the technology is and might take us, but for now you should know all the basics and be able to delve straight into the deep end.

If you’ve enjoyed this entry to the RHA Blog, or have any questions or comments about 3D printing, get in touch via the RHA Facebook or Twitter.